Behind the Scenes: The Development of Momentum Cycle Tools

Share

At Momentum Cycle, we believe that every cyclist deserves reliable, affordable and quality tools to keep their bike in top condition. Our journey began with a simple mission: to create affordable and durable user-friendly bike tools that meet the needs of every rider, from home mechanics to professional bike shops. Join us as we take you behind the scenes of the development of Momentum Cycle Tools, showcasing our commitment to excellence and the meticulous process that brings our products to life through 3D printing technology.

The Spark of Innovation

Momentum Cycle was born out of the idea to create affordable, reliable and durable tools for home mechanics that don’t want to break the bank to maintain their bikes. Our founder, avid cyclists himself, envisioned a line of tools that would combine strength, durability, precision and ease of use. With this vision in mind, a brand that cyclists could trust was then created from the ground up!

Research and Development: Turning Ideas into Reality

The development process for Momentum Cycle’s products begins with understanding the different problematics and what is involved in them. We start by listening to cyclists from all walks of life—home mechanics, professional bike shop owners, and everyday riders—to understand their needs and the challenges they face. This feedback forms the foundation of our product design. We then dive into the technical details, exploring materials, ergonomics, and mechanical functionalities.

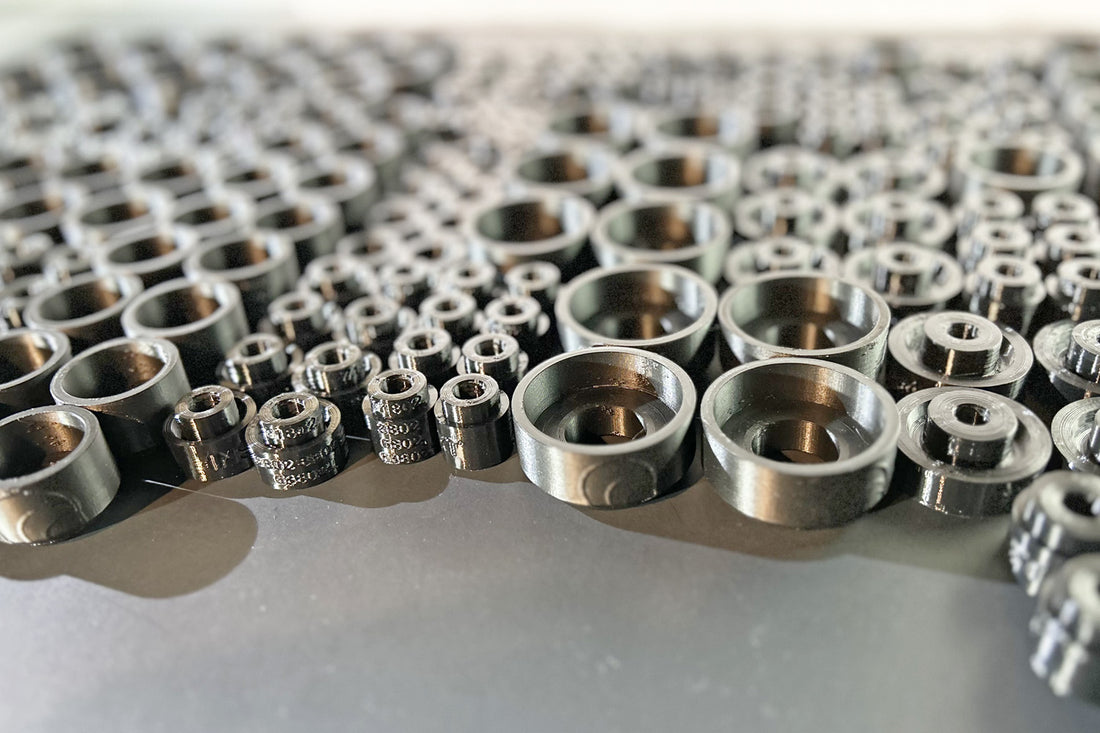

Based in Canada, our small team is passionate about cycling and how things work, which drives our innovation. We leverage 3D printing as our main manufacturing process, allowing us to rapidly create and test multiple iterations of our designs. This technology ensures that every product meets our standards of quality and affordability.

Feedback Loop: Continuous Improvement

We believe in continuous improvement. Once the initial prototypes have been tested, we gather feedback from our different testers, which includes home mechanics, professional bike shop owners, and avid cyclists. Their insights are invaluable and often lead to tweaks and enhancements that make our tools even better.

This feedback loop continues until we are confident that our tools meet our standards of quality and performance. The flexibility of 3D printing enables us to iterate quickly and efficiently, ensuring that our final products are the best they can be, and also allowing us to integrate improvements over time.

![]()

Manufacturing Excellence

When it comes to manufacturing, 3D printing is at the heart of our process. This cutting-edge technology allows us to produce durable, precise, and affordable tools. By using 3D printing, we can maintain high-quality standards while keeping our production costs low, which translates into cost savings for our customers.

Quality control is a top priority. Each tool undergoes thorough inspection before it leaves our facility in Canada. We want to ensure that every product that carries the Momentum Cycle name is something we can be proud of and something our customers can trust.

Launching the Product: Sharing Our Passion

Bringing a new tool to market is an exciting moment for us. It’s the culmination of months, sometimes years, of hard work. We take great care in launching our products, providing detailed information about their features and benefits to our customers.

We also offer hints, how-toes and guidelines to help cyclists get the most out of our tools and perform their bikes maintenance. Our goal is to empower riders with the knowledge and tools they need to take care of their bikes, enhancing their overall cycling experience.

Looking Ahead: The Future of Momentum Cycle

Our journey doesn’t end with the launch of a new product. We are constantly looking for ways to innovate and improve. The cycling world is always evolving, and we aim to keep developing tools that meet the changing needs of cyclists. Our continued use of 3D printing technology ensures that we can quickly adapt to new trends and demands in the cycling community.

We have exciting projects in the pipeline and can’t wait to share them with you. Stay tuned for more updates and innovations from us! We are committed to helping you enjoy the ride, wherever it may take you.

Join the Momentum Cycle Community

We invite you to join our community. Follow us on social media (Instagram and Facebook), subscribe to our newsletter, and stay connected with us. Share your stories, ask questions, and give us your feedback. Together, we can continue to push the boundaries of what’s possible in the world of cycling tools.

Thank you for being a part of our journey! Here’s to many more miles of smooth, enjoyable rides with Momentum Cycle Tools by your side.

Happy riding!