The Evolution of 3D Printing: Strength and Innovation in Modern Manufacturing

Share

In recent years, 3D printing has undergone a remarkable transformation, revolutionizing the manufacturing landscape. What began as a method for creating simple prototypes has evolved into a sophisticated technology capable of producing strong, durable, and complex parts. At Momentum Cycle, we leverage this technology to bring quality, reliable and affordable bike tools to our customers.

The Journey of 3D Printing

The journey of 3D printing, also known as additive manufacturing, started in the 1980s. Initially, it was primarily used for creating prototypes quickly and affordably. Early 3D printed parts were limited in strength and material variety, suitable mainly for design validation and fit testing.

However, the technology has seen significant advancements over the past decade. Innovations in materials, printing techniques, and machine capabilities have expanded the potential applications of 3D printing far beyond its initial scope.

Advances in Materials

One of the most significant advancements in 3D printing is the development of new, stronger materials. Early 3D printers primarily used plastics like ABS and PLA. Today, the range of materials includes high-performance polymers, composites, metals, and even ceramics.

Modern 3D printing materials are engineered for strength and durability. For instance, carbon fiber-reinforced polymers and metal powders like titanium and stainless steel enable the production of parts that can withstand significant mechanical stress. These materials sometime have comparable strength to traditionally manufactured parts, making them suitable for critical applications.

Improved Printing Techniques

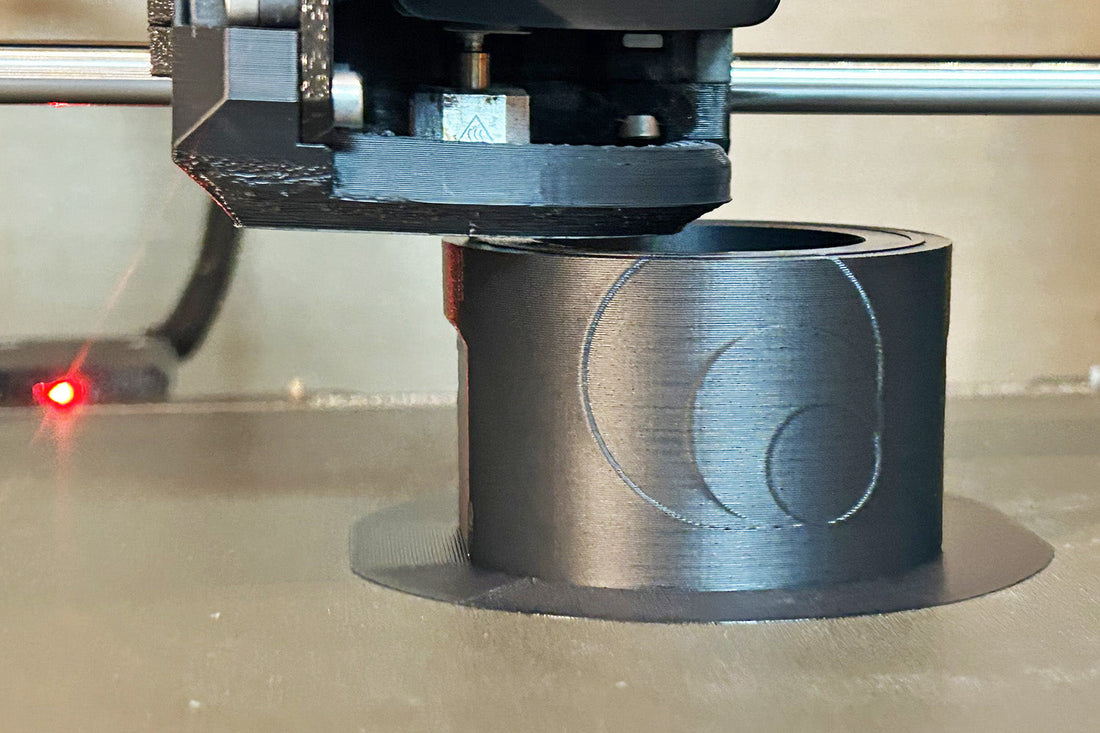

The evolution of printing techniques has also played a crucial role in enhancing the strength and precision of 3D printed parts. Techniques like Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM) have been refined to produce parts with higher resolution and better mechanical properties.

Multi-material printing and hybrid manufacturing processes allow for the creation of parts with complex geometries and varied material properties. This capability is particularly beneficial for producing intricate bike tools that require a combination of strength, flexibility, and precision.

Quality and Reliability

Modern 3D printing technologies enable the production of solid parts of consistent quality. Advanced software and machine learning algorithms optimize print parameters, reduce errors, and improve repeatability. Post-processing techniques enhance the mechanical properties and aesthetics of 3D printed parts.

See our Wheel Hub Axle Removal Tool, Hub Support and Freehub Adaptors

Real-World Applications

Today, 3D printed parts are used in a wide range of industries, from aerospace and automotive to healthcare and consumer goods. In the cycling industry, 3D printing allows us to create quality tools that meet the specific needs of our customers.

At Momentum Cycle, we use 3D printing to develop tools that are not only affordable but also robust and reliable. The strength of modern 3D printed parts ensures that our tools can withstand the rigors of regular use, providing cyclists with the durability they need.

See our Fork Seal Driver Tools

See our Bearing Press Kits and Cranks

The Future of 3D Printing

The future of 3D printing is incredibly promising. Ongoing research and development are focused on further improving material properties, reducing production costs, and expanding the range of printable materials.

As 3D printing technology continues to evolve, we at Momentum Cycle are excited to stay abreast of technological advances.

Join the Momentum Cycle Community

We invite you to join the Momentum Cycle community. Follow us on social media, subscribe to our newsletter, and stay connected with us. Share your stories, ask questions, and give us your feedback. Together, we can continue to push the boundaries of what’s possible in the world of cycling tools using 3D printing technology.

Thank you for being a part of our journey! Here’s to many more miles of smooth, enjoyable rides with Momentum Cycle Tools by your side.

Happy riding!

Appreciate the insights? Share with others!

Enjoyed this post? You may also like: